A Safer, Cleaner Way to Restore Equipment

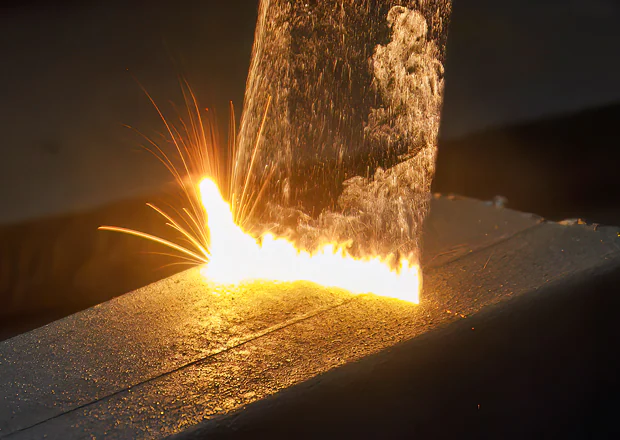

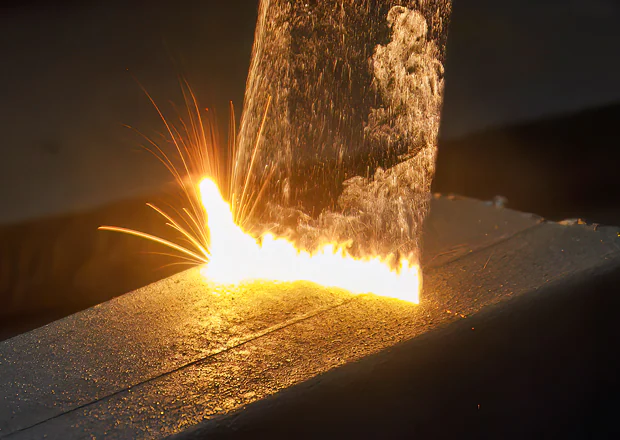

Industrial & Commercial Laser Surface Cleaning

Experience the future of surface restoration with our cutting-edge laser technology, designed to remove paint and coatings efficiently and safely.

Safe and Chemical-Free

Advanced Cleaning for Industrial & Commercial Environments

Industrial facilities and commercial operations rely on machinery, equipment, and infrastructure that must run clean, safely, and efficiently. Our laser surface cleaning solutions remove contaminants without chemicals, abrasive blasting, scrubbing, or machine teardown—reducing downtime and extending equipment lifespan.

Gentle on Surfaces, Tough on Coatings

Precision Cleaning for Machinery & Production Equipment

Laser cleaning is ideal for removing contaminants from durable metals and complex equipment geometries. Operators can clean machinery while components remain installed, helping facilities maintain uptime and prevent mechanical wear.

Common contaminant types include:

-

Grease & oil buildup

-

Grime & production residue

-

Carbon & soot contamination

-

Rust & oxidation

-

Hardened lubricants

-

Corrosion layers

-

Paint & protective coatings

Ideal for Complex Machinery & Large Components

Laser cleaning excels where brushes, solvents, or blasting cannot reach. This includes equipment with:

-

Large gears & gear trains

-

Bearings & housings

-

Tooling surfaces

-

Injection Mold Cleaning

-

Extrusion lines

-

Conveyor assemblies

- Heavy fabrication equipment

-

Foundry components

-

CNC and automated systems

By using directed laser energy, contaminants are removed without disassembly, abrasive wear, or chemical waste streams.

Industrial & Commercial Use

Our laser systems support a wide variety of facility types and workflows, including:

- Manufacturing & fabrication plants

-

Foundries & forge shops

-

Automotive & aerospace facilities

- Heavy equipment & machinery shops

-

Rail & marine maintenance yards

- Machinery

-

Power generation facilities

-

Food & beverage processing (non-contact applications)

-

Building maintenance & restoration

-

Contractor specialty cleaning services

-

HVAC & mechanical contractors

-

Facility management companies

Benefits for Businesses

Compared to abrasive blasting, chemicals, or shutdown-intensive cleaning, laser systems provide:

-

Minimal downtime — clean in place, no major teardown

-

Non-destructive — no abrasion or surface erosion

-

Chemical-free process — reduce hazardous waste & disposal costs

-

Precision control — focus only on contamination, not the base metal

-

Cleaner workflows — reduced mess, less PPE, minimal containment

-

Operator safety — enclosed or filtered systems minimize exposure

Laser cleaning helps businesses stay compliant, minimize maintenance budgets, and prevent component failure caused by buildup.

Non-Destructive

Our laser technology ensures that the underlying surface remains intact and undamaged.

Chemical-Free

Eliminate the need for harsh chemicals, making the process safer for both the environment and operators.

Minimal Waste

Generate significantly less waste compared to traditional methods, promoting a cleaner workspace.

Perfect for Maintenance, Overhauls & Field Service

Laser cleaning supports different maintenance models:

-

Preventive Maintenance (PM)

-

Predictive Maintenance (PdM)

-

Overhaul & Rebuild Cycles

-

Field Service & Repair

-

Pre-Inspection Surface Prep

Because lasers don’t rely on chemicals or media, cleanup time is drastically reduced and equipment can return to service faster.

Applications and Surfaces

Whether the goal is to restore, prep for finishing, or remove contaminants, laser cleaning adapts to multiple material types without damaging the underlying surface. Select a material category below to learn more.

Our laser technology is ideal for preparing surfaces for welding, ensuring a clean and precise bond. It's also perfect for painting prep, removing old coatings without damaging the substrate. For NDT inspections, our method provides a pristine surface for accurate results. Additionally, we specialize in historical restoration, gently removing layers to reveal original materials without harm.

Metal

Stone

Wood

Why Choose Laser Over Traditional Methods?

Discover the advantages of laser cleaning compared to sandblasting and chemical methods.

Laser Cleaning

No Abrasives

Chemical-Free

No Surface Damage

Minimal Cleanup

Eco-Friendly

Traditional Methods

Uses Abrasives

Chemical Usage

Potential Damage

Extensive Cleanup

Less Eco-Friendly

Request an On-Site Evaluation

Every industrial or commercial environment has different types of contaminants, production requirements, and safety standards. We provide site evaluations, equipment demonstrations, and service proposals tailored to your facility.