A Safer, Cleaner Way to Remove Soot

Laser Soot Removal from Smoke & Fire Damage

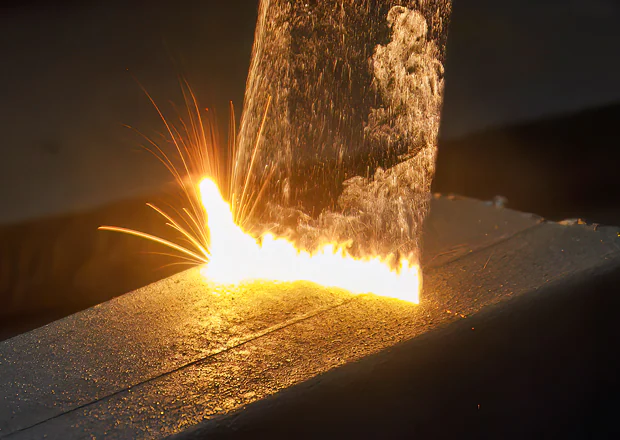

Soot from smoke and fire events can deeply contaminate surfaces, stain building materials, and leave behind hazardous residue. Our laser cleaning technology removes soot, carbon deposits, and smoke contaminants without grinding, blasting, or chemicals—making it ideal for restoration, conservation, and building remediation work.

Safe and Chemical-Free

Why Laser Cleaning for Soot & Smoke Damage?

Soot contamination is often difficult to remove using conventional cleaning methods, especially on porous, textured, or historically sensitive surfaces. Laser cleaning vaporizes soot and carbon buildup at the surface level without damaging the material beneath, helping restore surfaces safely and accurately.

Key advantages include:

Benefits of Laser Paint and Coating Removal

-

No chemicals or solvents

-

No abrasive blasting or scrubbing

-

No micro-pitting or material loss

-

Reduced cross-contamination

-

Cleaner, safer restoration process

-

Minimal secondary waste

Advanced Laser Technology for Surface Protection

Non-Destructive

Our laser technology ensures that the underlying surface remains intact and undamaged.

Ideal Surfaces & Materials

Laser soot removal is effective on a wide range of building materials and surfaces, including:

-

Stone (limestone, marble, granite)

-

Brick & concrete

-

Wood beams & decorative features

-

Metal fixtures & components

-

Historical building materials

-

Industrial machinery

-

HVAC housings & equipment

-

Siding, structures, & architectural details

Applications & Industries

This service is commonly used in:

-

Fire & smoke restoration projects

-

Historic building conservation

-

Residential & commercial property cleanup

-

Industrial facility remediation

-

Insurance restoration claims

-

Museums & cultural preservation

-

HVAC and equipment cleaning

Laser cleaning allows restoration teams to remove soot without over-cleaning, surface wear, or chemical exposure—especially valuable for high-value or irreplaceable materials.

Applications and Surfaces

Whether the goal is to restore, prep for finishing, or remove contaminants, laser cleaning adapts to multiple material types without damaging the underlying surface. Select a material category below to learn more.

Metal

Stone

Wood

Why Choose Laser Over Traditional Methods?

Discover the advantages of laser cleaning compared to sandblasting and chemical methods.

Laser Cleaning

No Abrasives

Chemical-Free

No Surface Damage

Minimal Cleanup

Eco-Friendly

Traditional Methods

Uses Abrasives

Chemical Usage

Potential Damage

Extensive Cleanup

Less Eco-Friendly

Get a Free Quote or Consultation

Ready to experience the benefits of laser cleaning? Contact us today to schedule a consultation or request a free on-site demonstration. Our team is eager to show you how our advanced technology can meet your surface preparation needs efficiently and effectively.